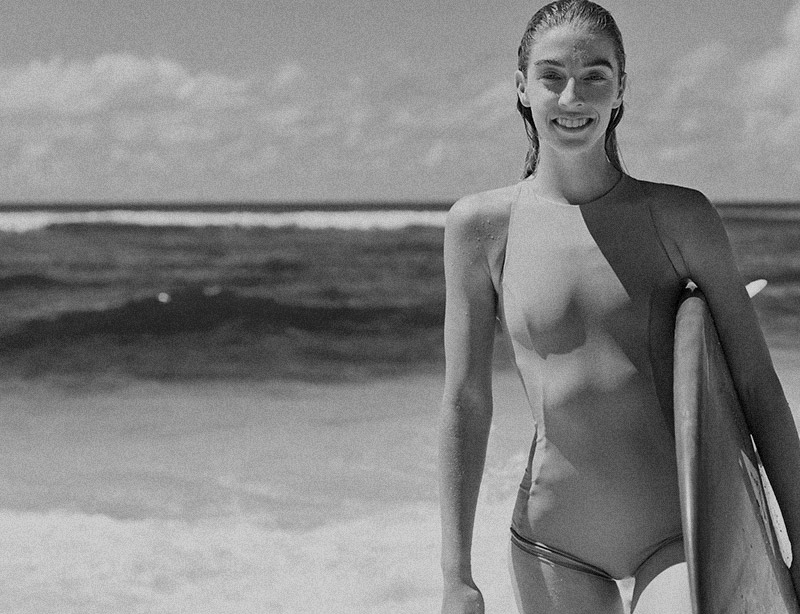

From Concept to Cresting Waves

At Infront Surfcraft, our production process is an art form, meticulously honed to create surfboards that are not just tools, but extensions of the surfer’s soul. Here’s a glimpse into our journey from conception to the final product:

Design and Shaping

The journey begins with our expert design team, who use advanced CAD software to create innovative surfboard designs. These designs are then brought to life in our shaping bay, where precision machinery and skilled craftsmanship work in harmony to sculpt the perfect surfboard shape. This stage blends art with technology, ensuring every board is both aesthetically pleasing and performance-driven.

Lamination and Reinforcement

Next, we move to the lamination process, a crucial step for durability and performance. Here, high-quality materials like fiberglass and eco-friendly resins are meticulously applied to the shaped core. This stage not only reinforces the board but also ensures it’s lightweight and responsive to the surfer’s movements.

Artwork and Finishing

Each surfboard is then transformed into a piece of art. Our talented artists and technicians apply custom graphics and finishes, giving each board a unique identity. This process is not just about visual appeal; it also involves fine-tuning the board’s surface for optimal performance.

Quality Control and Testing

Finally, every surfboard undergoes a rigorous quality control process. We conduct detailed inspections and performance tests to ensure that each board meets our high standards of excellence. This final step guarantees that our surfboards are not just ready for the market, but ready to excel in the waters they’re destined for.

At Infront Surfcraft, our streamlined four-step production process ensures each surfboard is a perfect blend of functionality, beauty, and durability, ready to ride the waves with unmatched performance.